Vacuum Group

Brief Introduction

The Vacuum Group is mainly responsible for the operation, maintenance, and upgrading of the vacuum system of the Lanzhou Heavy Ion Research Facility (HIRFL) as well as research and manufacturing of vacuum systems for new accelerators. There are currently 18 scientific researchers in the group.

The group has undertaken the construction task of the vacuum system of HIRFL-CSR, a National "ninth Five-Year Plan" Major Scientific Engineering Project, and successfully obtained extremely high vacuum in the range of 10-10Pa, which was the best index that could be obtained by large vacuum systems in China and similar international devices.

In addition, the group has completed the research and development of vacuum systems for the Heavy Ion Medical Accelerator, and overcome some processing technical problems such as thin-walled reinforced structure vacuum chambers, runway bellows, and special-shaped ceramic vacuum chambers.

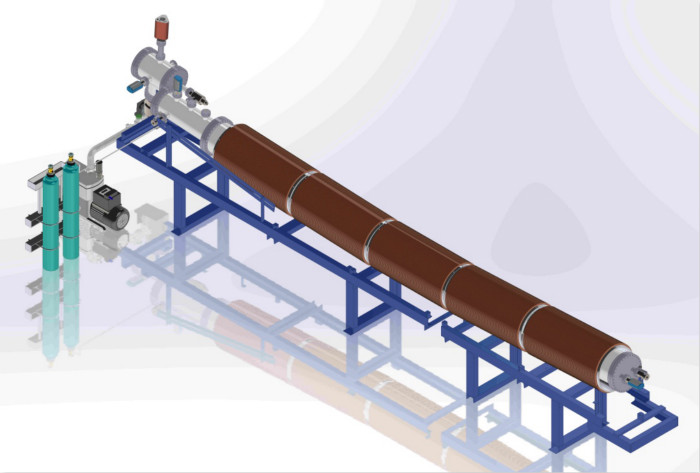

At present, the group is undertaking the design and key prototype development tasks of the High Intensity heavy-ion Accelerator Facility (HIAF) ultra-high vacuum system. It is the first time in the world to propose a new method of ceramic-lined thin-wall vacuum chamber, and a principle prototype has been developed. The vacuum degree of this prototype has reached the range of 10-10Pa, and the gap of the magnet can be greatly reduced, which is the direction of the thin-walled vacuum chamber of the accelerator in the future.

In order to suppress the "dynamic vacuum effect" generated by HIAF during operation, the group developed the technology of coating Au film on the ceramic surface and NEG getter film on the surface of a large curved vacuum chamber. This technology aims to effectively reduce the desorption rate of vacuum materials, greatly improve the getter’s capacity and service life of NEG getter films, and break the bottleneck of the development of NEG thin film technology at home and abroad.

At the same time, in order to reveal the law of the desorption rate of vacuum materials at room temperature and low temperature, the group explored a new method to maintain the stability of the dynamic vacuum system in the HIAF, and carried out the measurement of the desorption rate of vacuum materials and obtained a series of important experimental data. In addition, a double-channel double-sealed inflatable expansion flange with good sealing performance and strong radiation resistance (dose up to: 500Gy/h) was successfully developed.

Through nearly 30 years of efforts, the Vacuum Group has managed to obtain ultra-high/extremely-high vacuum, and are able to design and manufacture ultra-high / extremely-high vacuum systems, which are helpful for the operation of a series of high-level physical experiments and the construction of HIAF.

Research Fields

To aim at the forefront of international accelerator vacuum technology, the Vacuum Group carries out research on the technology of obtaining ultra-high\ extremely-high vacuum for large accelerators, and provides the vacuum technology support for the High Intensity heavy-ion Accelerator Facility and heavy ion cancer treatment devices. Aiming to build a leading domestic and international research team on accelerator ultra-high / extremely-high vacuum acquisition technology, the group's main research directions are divided into the following five categories:

1. Design and technology of normal temperature and extremely-high vacuum system, including: new technology for obtaining extremely-high vacuum, design scheme for exhaust of extremely-high vacuum, dynamic vacuum simulation technology of accelerator, etc.

2. Design and technology of cryogenic extremely-high vacuum system, including: development of cryogenic thin-wall vacuum chamber, cryogenic adsorption pump technology, cryogenic collimator design, etc.

3. Vacuum chamber surface coating technology, including: NEG film, Au film, TiN film, etc.

4. Vacuum material desorption rate measurement technology, including: room temperature material desorption rate measurement, low temperature material desorption rate measurement, etc.

5. Development of special-shaped vacuum chambers, including: ceramic-lined thin-walled vacuum chambers, special-shaped ceramics vacuum chambers, extremely-high-vacuum thin-wall reinforced stainless steel vacuum chambers, etc.

Achievements

I. Representative papers:

1. The ultra-high vacuum system of HIRFL-CSR[J]. Vacuum ,2001,61: 55—60.

2. The first prototype of the HIRFL-CSR UHV system[J]. Vacuum ,2003, 68: 11–18.

3. Reserch for a Clean and Large Throughput Differential pumping Systerm [J]. Chinese Physics C,2008,32:59—61.

4. Gettering of TiZrV Coatings on Pipe Inner-Walls of Vacuum System[J]. CHINESE JOURNAL OF VACUUM SCIENCE AND TECHNOLOGY, 2009(06):678—681.

5. Evaluation of High Temperature Outgassing Rates of Stainless Steel in Method of Switching between Two Pumping Paths [J]. CHINESE JOURNAL OF VACUUM SCIENCE AND TECHNOLOGY, 2011,31(3):368—371.

6. Development of Large-Sized Window of Heavy Ion Accelerator Used As Cancer Therapy Terminal[J]. CHINESE JOURNAL OF VACUUM SCIENCE AND TECHNOLOGY, 2012,32(1):59—62.

7. Use of combined sputter ion and NEG pumps in the heavy ion medical machine[J]. Vacuum ,2015,114:108—113.

8. Application of compact NEG-sputter ion pump combination in UHV system of HIAF[J]. Vacuum ,2018,157:159—165.

9. Development of Thin-Wall Vacuum Chamber for Heavy Ion Medical Accelerate.[J]. Atomic Energy Science and Technogy. 20200320.1321.004.

II. Invention Patents

1. A non-metal vacuum isolation window capable of passing particle beam: CN102103968B [P].2013 -02-13.

2. Manufacturing method of thin-wall vacuum pipe and vacuum chamber made of thin-wall vacuum pipe: CN102348321B [P].2013-08-21

3. Device and method for testing and optimizing ion pump performance CN109707612B [P].2020-01-17

III. Awards

Lanzhou Heavy Ion Accelerator Cooling Storage Ring Ultra High Vacuum System Prototype: Second Prize of Science and Technology Progress Award of Gansu Province, 2004.

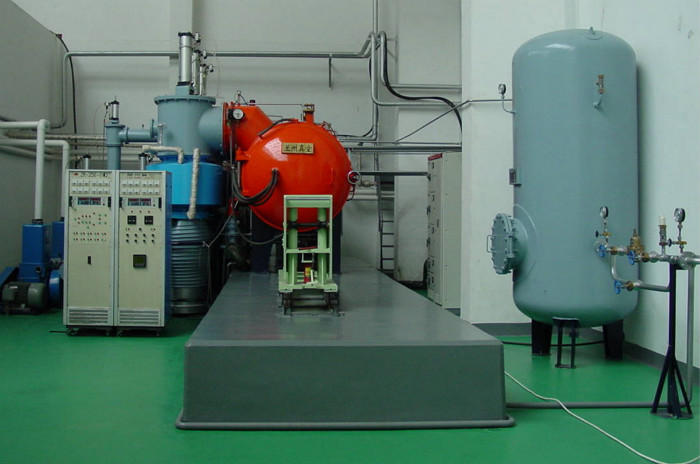

Photos

Contact

LIU Jianlong

Phone:+86-15343693371

Email: liujl@impcas.ac.cn

Mailing Address: 509 Nanchang Road, Lanzhou, 730000, China

甘公网安备 62010202000713号

甘公网安备 62010202000713号