Researchers Report a Surface Modification Method to Improve Corrosion Resistance of Steel to Liquid Lead-bismuth Eutectic

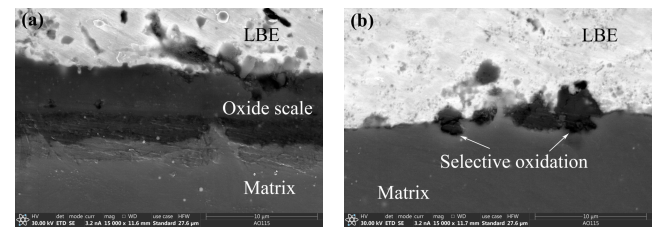

Fig.1 Cross-sectional SEM morphologies of (a) the original and (b) the surface nanocrystallised SIMP steels after exposure to oxygen-saturated liquid LBE at 550℃ for 120 h. (Image by MA Zhiwei)

Lead-cooled fast reactor, using lead or lead-bismuth eutectic (LBE) as the coolant, is one of the six recommended reactor types for Generation IV nuclear reactors due to its excellent physical properties. However, the compatibility issue between coolant and structural materials has become one of the major constraints to the development of lead-cooled fast reactors.

It is therefore important to find ways to improve the resistance of structural materials to LBE. Studies have shown that surface nanocrystallization can alter the physicochemical properties of the material surface, and thus improve the service performance of the material.

Recently, researchers at the Institute of Modern Physics (IMP), Chinese Academy of Sciences (CAS), used the shot peening (SP) process to nanocrystallise the surface of ferrite/martensitic steel SIMP, a candidate structural material for lead-cooled fast reactors. They investigated the corrosion behaviour of the SP samples exposed to liquid LBE, in comparison with that of the original coarse grain (CG) samples.

The corrosion experiments of the SP and CG samples were carried out in liquid LBE saturated with oxygen at 550℃ for different durations from 120 h to 1218 h. It is found that a gradient nano- and submicron-structured surface layer of SIMP steel was produced by means of SP.

Compared with the original CG samples, the oxidation resistance of the SP samples is significantly improved. This is owing to the fact that the large number of grain boundaries and dislocations introduced by SP enhances the diffusivity of Cr, making it easier to form enhanced Cr-rich oxides. Meanwhile, the magnetite layer of the SP samples has higher compactness, giving it better resistance to exfoliation than that of the original CG samples.

The study provides an important technical process for improving the LBE corrosion resistance of lead-cooled fast reactor structural materials, which has great significance for improving the service performance of structural materials.

Fig.2 Variations of oxide thickness with exposure time in oxygen-saturated liquid LBE at 550℃ for the original (CG) and the surface nanocrystallised (SP) SIMP steels. (Image by MA Zhiwei)

The study was published in the journal of Applied Surface Science.

This work was supported by the National Natural Science Foundation of China and the Instrument Developing Project of CAS.

Contact Information

Institute of Modern Physics

Email: fangliu@impcas.ac.cn

甘公网安备 62010202000713号

甘公网安备 62010202000713号