Researchers Obtain New Results on Corrosion Behavior of Alloy Materials under Extreme Environments

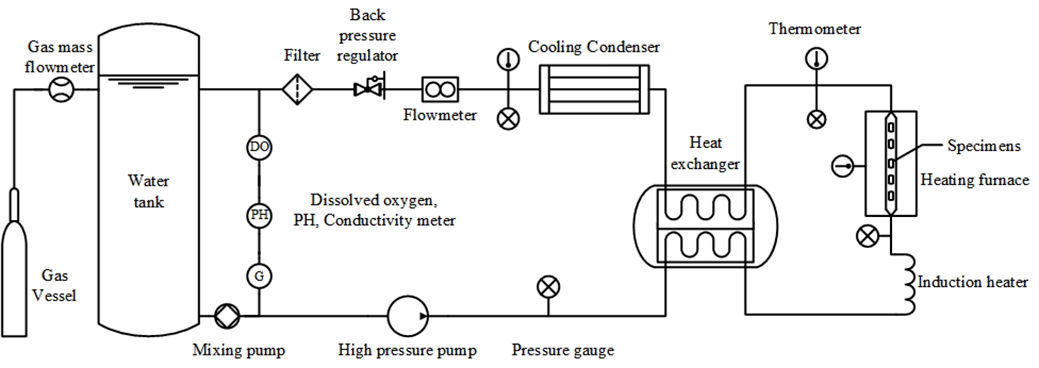

Fig. 1. Schematic diagram of the high temperature and high pressure water dynamic corrosion device. (Image by LIU Chao)

The service behavior of materials under extreme environments is one of the bottlenecks restricting the development of advanced nuclear energy systems. Researchers at the Institute of Modern Physics (IMP) of the Chinese Academy of Sciences have lately obtained new results on the corrosion behavior of alloy materials under strong irradiation, high temperature and coolant corrosive environments.

To simulate the environment faced by the structural materials of supercritical water-cooled reactors, researchers at IMP have independently designed and built a high temperature and high pressure water dynamic corrosion test device, whose maximum operating temperature, pressure and water flow rate are respectively 700 ℃, 10 MPa and 10 m/s, and minimum oxygen concentration is 5 ppb.

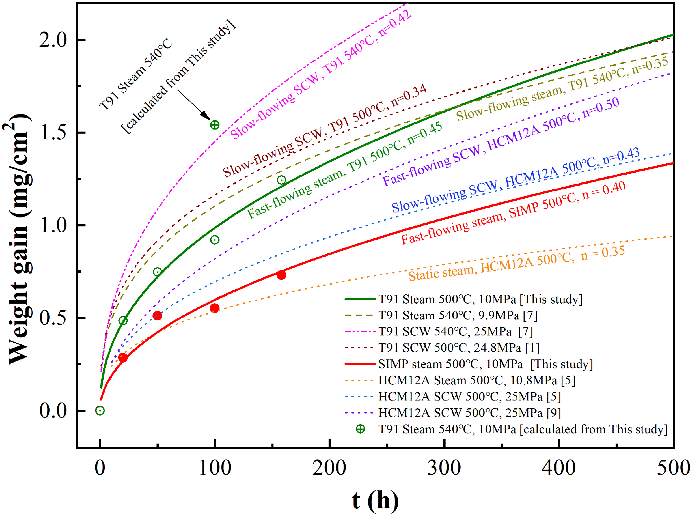

Ferrite-martensitic steels SIMP and T91 are proposed as candidate materials for the supercritical water-cooled reactor. Researchers studied both the high temperature water corrosion kinetics and the corrosion behavior of SIMP and T91 under irradiation by using the Heavy Ion Research Facility in Lanzhou and the high temperature and high pressure water dynamic corrosion device.

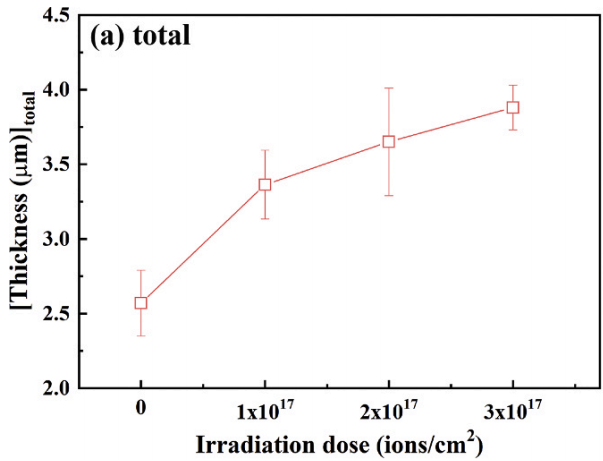

It is found that SIMP steel has better water corrosion resistance than T91 steel. The corrosion rate is enhanced by the flow rate, which also has a significant effect on the phase of the oxide film. The results of heavy ion pre-irradiation experiments confirm that irradiation causes a significant increase in the corrosion rate of materials. According to the experimental results, researchers also discussed the high temperature water corrosion behavior of the material and the mechanism of corrosion resistance degradation under irradiation.

These achievements provide not only an important research platform, but also experimental methods for the rapid screening and evaluation of candidate materials for advanced water-cooled reactors.

Fig. 2. Corrosion kinetics curves of SIMP and T91 steels (5m/s, 5ppb). (Image by LIU Chao)

Fig. 3. Variation of oxide film thickness of T91 steel with irradiation dose (450℃, 5m/s, 10MPa, 5ppb). (Image by LIU Chao)

The related results have been published in Corrosion Science, an international top journal in the field of material Corrosion.

The research work was supported by Joint Key Project of National Natural Science Foundation of China, Key Deployment Project of Chinese Academy of Sciences and Lanzhou Heavy Ion Accelerator National Laboratory.

The papers are available at:

https://doi.org/10.1016/j.corsci.2021.109602

https://doi.org/10.1016/j.corsci.2021.109474

Contact Information

Institute of Modern Physics

Email: fangliu@impcas.ac.cn

甘公网安备 62010202000713号

甘公网安备 62010202000713号