Progress in Fabrication of Simulated Ceramic Nuclear Fuel Spheres

The closed nuclear fuel cycle has important strategic significance for the sustainable development of nuclear energy. The reutilization of spent fuel is the most important step of the closed nuclear fuel cycle. It can improve the utilization rate of uranium resources, minimize the amounts of radioactive wastes and solve the geological disposal problem of the high-level radioactive wastes efficiently. There are many strategies for the handling of radioactive wastes, among which transmutation is considered as the most effective and environment-friendly solution. Sub-critical accelerator driven system (ADS) is a potential way to transmute long-lived nuclides into short-lived or stable nuclides by the fast neutrons. For the spent fuel from pressured-water nuclear power plants (NPP), most of the volatile fission products can be removed by the high-temperature oxidation-reduction process. The radioactivity comes from the remaining uranium (U), plutonium (Pu) and long-lived minor actinides (MAs) including neptunium (Np), americium (Am), and curium (Cm). Therefore, an important issue is the fabrication of ceramic nuclear fuel with a high fraction of MAs and Pu for ADS reactors.

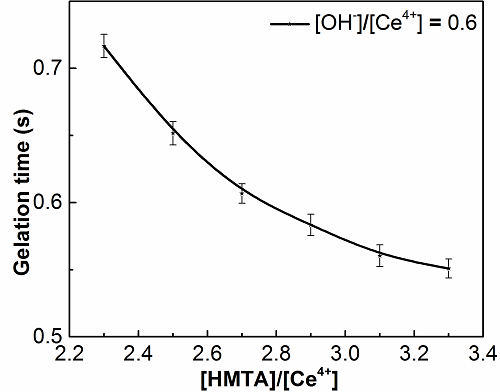

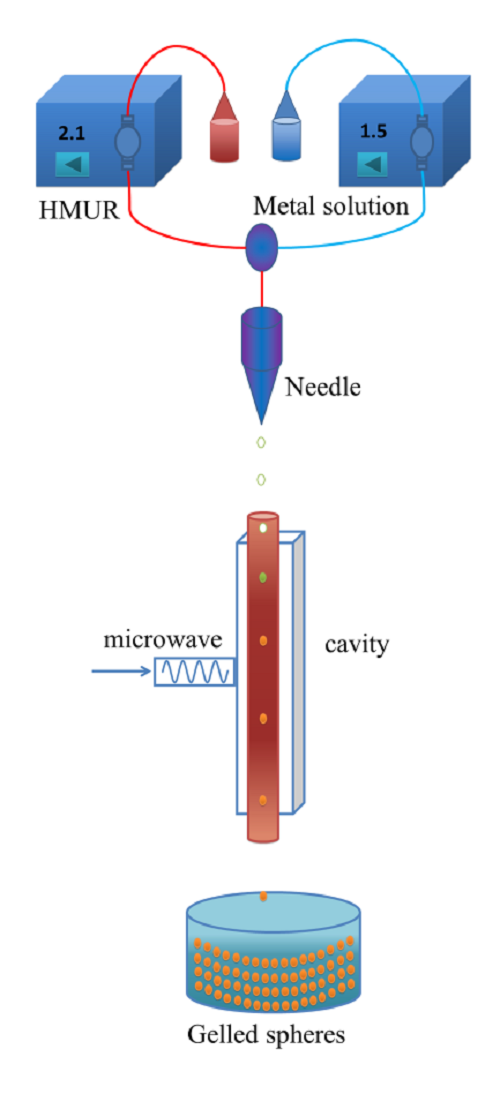

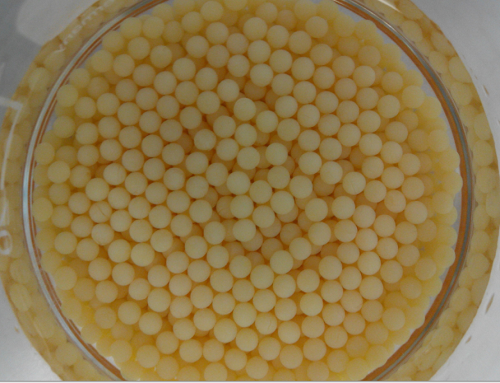

Under the cooperation between PSI and IMP, the chemical kinetics of the internal gelation process was systematically investigated, and it indicated that the process can be accomplished quickly by adjusting the composition of the feed solution. Therefore, an improved internal gelation process, which combined the in-situ instant mixing of room-temperature precursor solutions with microwave-assisted internal gelation, was proposed to fabricate MA-containing ceramic nuclear fuel spheres. In addition, experimental apparatuses were developed in PSI and IMP respectively, and uniform sized ceramic CeO2 spheres with a diameter of 500±12 μm were successfully fabricated based on the apparatus. The improved microwave-assisted internal gelation process greatly simplifies the conventional sol-gel process. Furthermore, it reduces the radiolysis effects on the HMUR precursor solution and avoids secondary organic radioactive waste. It will be a potential method for the fabrication of MAs and Pu-containing ceramic nuclear fuel spheres in glove-box for the ADS project in future.

This work was financially supported by the CAS Strategic Priority Research Program and the Chinese National Nature Science Fund. The work has been published in the international top journal Ceramic International.

The article link: https://www.sciencedirect.com/science/article/pii/S0272884218301044

Fig. 1. Chemical kinetics investigation of the internal gelation process

Fig. 2. Schematic of the improved microwave-assisted rapid internal gelation process

Fig. 3. CeO2 gelled spheres

甘公网安备 62010202000713号

甘公网安备 62010202000713号